含重金属尾矿的绿色资源化利用研究进展

摘要:随着金属资源的不断开发,大量堆积的重金属尾矿已经成为目前环保邻域主要污染来源之一,由于国家和社会环保的越来越重视,重金属尾矿已经严重制约了金属冶炼行业的发展;本文在响应习近平同志提出的绿色发展的同时综述了重金属尾矿的危害以及近些年来重金属尾矿无害化、减量化、资源化现有处理技术,为金属尾矿矿山治理总结了研究经验,针对金属尾矿大量堆积、无法大批量消纳、造成持久性环境污染等问题,提出了重金属尾矿能大批量消纳的土壤化利用技术,缓解我国多地土地贫瘠等问题的同时解决了重金属尾矿大批量出路问题。

关键词: 尾矿;重金属;无害化;减量化;资源化

0引言

2021年正式开启全面建设社会主义现代化国家的中国仍将是在全球经济衰退后拉动经济增长的主要动力,作为能源和工业主要原料的矿产资源需求将持续增长[1]。我国矿产资源种类多、储量大,但随着需求增加、长期无序及过量开采、冶炼技术进步,大量堆积的尾矿不仅使矿山生态恢复更加困难,而且铜、砷、铬和汞等重金属及其化合物经复杂的迁移转化后释放到环境中,严重威胁矿山及周边地区生态安全[2,3]。加强污染防治和生态建设、加大生态环境治理力度、严格土壤污染源头防控、推进生态系统保护和修复仍将是我国生态文明建设的重点方向。

土壤是地球表层系统中,生物多样性最丰富,生物地球化学的能量交换、物质循环最活跃的生命层,是有毒污染物的缓冲带和过滤器,但它也是有毒金属污染物的聚集地[4]。以重金属污染土壤修复为基础的热脱附[5]、淋洗[6]、电动处理[7]、微生物修复[8]等单一或联合修复技术应用于尾矿重金属去除以降低其资源化利用风险,但受尾矿性质及重金属特征的限制,仍面临综合利用率低的困局。

1尾矿重金属去除技术研究进展

1.1尾矿成因与危害

采矿后的裸露剥离区、尾矿坝和废石堆积区是矿山环境主要污染源,特别是低有机质、高酸度以及含大量低稳定性重金属(砷、镉、铜、锰、铅等)和氰化物的尾矿坝容易对生态系统造成严重的破环,威胁人类健康[9,10]。尾矿中不同价态、形态重金属的迁移转化差异显著,受尾矿尾砂粒径、pH、含水率等理化性质影响较大[11];尾砂中的重金属常以含硫化物和氧化物形式存在,当环境酸碱条件变化时容易形成高毒物质向环境中迁移[12];大量尾矿堆积一段时间后会产生高温厌氧环境,导致植物繁殖体和其他土著微生物显著减少或死亡,生态功能难以恢复和重建[13];此外,选矿过程中添加的有毒有害化学药剂也是环境污染的潜在来源[14]。

尾矿库是在初始结构初期坝和排洪系统的基础上随选矿逐步堆积加高的,我国自2001年以来,由于设计、选址不合理,加高过程中偏离设计施工、施工质量差以及受自然因素影响等造成溃坝和尾矿泄漏占到尾矿总事故数量的96.33%[15]。2015年甘肃陇南尾矿库大量矿浆泄漏,造成甘肃、陕西和四川三省境内严重的水污染,严重威胁嘉陵江流域内的饮水安全和生态安全[16,17]。近年来,巴西发生的两起Fundão和Córrego do Feijão尾矿坝溃坝是其境内最严重的环境事故,引起了河段内生物生化和形态变化,甚至矿浆在流域内沉降造成了严重的持续性污染[18]。

1.2尾矿综合利用情况

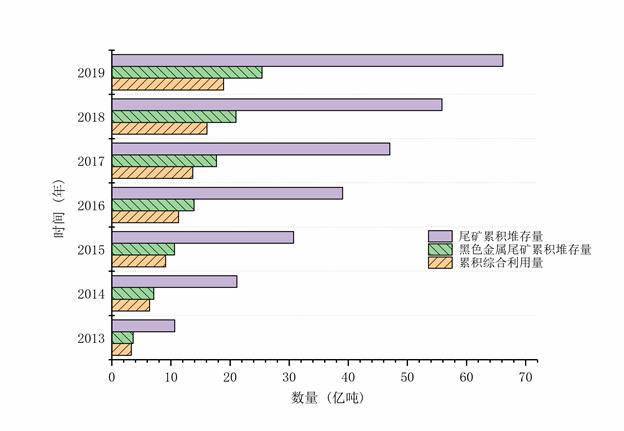

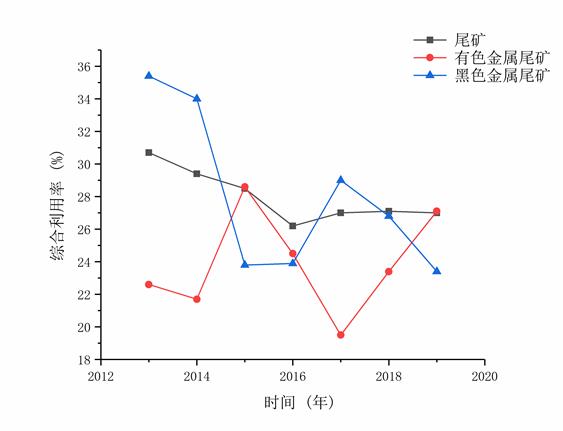

根据生态环境部发布的大中城市固体废物污染环境防治年报,图1为2013年以来全国大、中城市尾矿累积堆存和综合利用情况[19]。由图1可以看出与基础设施建设密切相关的铁锰黑色金属采选后产生的尾矿逐年增加,近七年来尾矿累积堆存量已超50亿吨。正如图2中所看到的,自2013年以来尾矿综合利用率降低了3.70%,重金属潜在威胁较大的有色金属尾矿的综合利用率也一直处于较低水平,多年累积下来对环境造成了不可忽视的影响。总的来说,我国尾矿综合利用与国外仍存在较大差距,堆存量仍在不断增加,尾矿综合处理处置任重而道远。

图1 2013年以来全国大、中城市尾矿累积堆存和综合利用情况

图2 2013-2019年大、中城市尾矿综合利用情况

1.3尾矿重金属去除技术

尾矿重金属毒性和理化特性直接影响到尾矿综合利用和矿山的生态重建和恢复,其中重金属形态、含量及迁移转化特征都是制约其资源化利用的因素。虽然已有许多材料能明显改善尾矿理化性质和限制重金属向周围环境迁移转化,但是对于尾矿中不同金属及类金属的作用各不相同,复合作用下甚至可能增加其有效性,从而威胁人类健康及生态安全,重金属去除成为尾矿资源化利用至关重要的环节。

(1)热脱附技术

热脱附是一种通过直接或间接热交换使污染物加热到一定温度后使其分离的技术,适用于处理大多数挥发性和半挥发性污染物,除了能去除多环芳烃、多氯联苯、石油烃等有机污染物外,对汞、砷或硒去除效果较好,国外早已经开始使用热脱附技术修复受污染土壤[20]。根据尾矿重金属不同形态以选择相对应的去除温度能有效提取出不同形态的汞,添加不同材料可以减少热处理过程中其它重金属的浸出[21]。

(2)淋洗技术

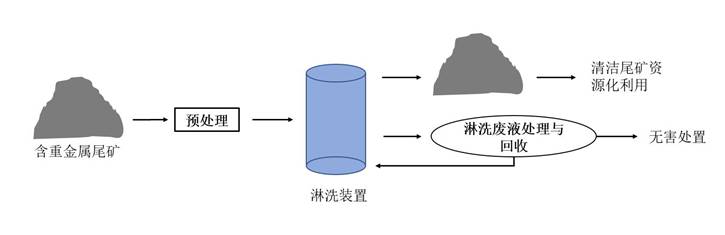

重金属淋洗的作用机制在于利用淋洗液或化学助剂与污染物结合,并通过解吸、螯合、溶解等化学作用来达到重金属去除的目的。一般情况下,淋洗也兼有清洗的作用,如图3所示,其主要工艺可分为颗粒筛分、淋洗处理、固液分离、废液处理四步。

图3 含重金属尾矿淋洗去除流程

大量的无机浸出剂、螯合剂、表面活性剂、复配浸出剂、氧化还原剂等淋洗剂已有用于控制土壤重金属污染的记录[22]。液固比为10:1,盐酸淋洗25分钟可去除67%的锌,使用0.5mol/L的磷酸溶液浸出120分钟能去除24.5%的砷[23,24],XinKe等[25]发现使用浓度为0.1M、pH为5的柠檬酸对冶炼厂土壤重金属的去除率为89.1% Cd、26.8% Pb、41.7% Zn、14.2% Cu,对重金属可交换性、碳酸盐结合态和氧化物结合态去除效果较好,离子液体和纳米材料也常用作尾矿重金属去除材料,Fenghui Wu等[26]使用[Hmim]SbF 6和纳米铁(H/Fe)的复合物作为吸附剂对溶液中砷的去除率可达99%。淋洗剂复合联用、添加淋洗助剂等优化措施对难溶重金属有明显去除作用,有研究表明螯合剂比酸溶液具有更高的金属提取效率,而且和金属盐类联合使用后对pH、总氮、可交换性钙等性质影响较小[27,28]。

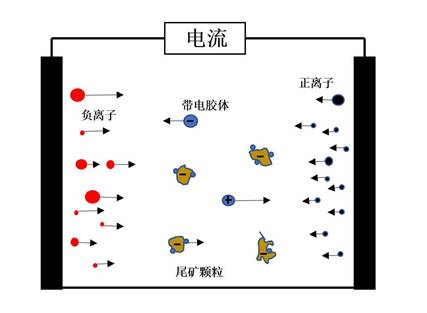

(3)电动处理技术

传统的电动处理主要是用于修复重金属污染土壤,特别是对低渗透性土壤有较好去除效果。重金属通常被吸附在细颗粒中,可通过电流引起电极和被污染的基质之间的反应而助于提取和溶解金属离子。Rodrigo Ortiz-Soto等[29]发现在H2SO4溶液和电场2V/cm时铜矿尾矿中锰、锌的电迁移有所增强,其去除率分别为31.88%和17.95%。电压梯度对金属离子迁移浓缩有决定性的影响,可通过增加电压梯度、电流强度和电渗透流量来强化其过程[30]。然而,金属离子易与阴极电解反应产生的氢氧根离子结合沉淀,并且在阴极极化现象的影响下严重削弱了电动去除效果,脉冲电流周期性地流过阴极可减弱极化现象,通过影响pH和电导率来减少金属沉淀[31,32]。

图4 含重金属尾矿电动处理技术

(4)微生物去除技术

微生物是尾矿生物中最活跃的组分,其数量、种群组成、多样性等构成了尾矿发育及其特点的关键要素,参与系统中物质循环、能量转换以及重金属迁移转化等一系列重要生态过程,对维持尾矿重金属稳定性和促进矿山生态恢复有重要作用。

尾矿中土著菌种对重金属具有较高耐受性,将其从尾矿中分离驯化后再投入到尾矿治理是一种经济可行的方法。A. Giridhar Babu等[33]将分离的耐重金属真菌-木霉PDR-28用于尾矿修复,显著提高了植物根系和地上部分生物量,植物根系重金属含量分别增加了25%(Cu)、62%(Cd),地上部分重金属含量增加 35%(Cu)、64% (Pb),Jie Li等[34]从锑矿土壤中分离出抗锑细菌,研究发现其具有较强的锑抗性和锑氧化能力。Van Khanh Nguyen[35]也从锑污染土壤中分离到锑氧化细菌,研究发现两种菌株都能在营养有限的条件下氧化锑生成锑,并且在厌氧和好氧条件下都对As和Sb表现出氧化性,对尾矿As、Sb去除具有较大的应用潜力。利用耐重金属植物或者是超富集植物,可使土壤中重金属活性降低,减少重金属迁移转化。Muhammad Rizwan等[36]研究发现香丝草营养积累能力较强并且对矿区有毒污染物表现出较高的耐性。此外,与植物根系相关的一些根际微生物群落除了自身的相互作用外,还会与植物发生相互作用,虽然有耐性植物能在尾矿上生长,但是接种根际微生物能显著降低植物根际重金属有效性,促进植物生长和植被恢复[37]。

(5)多物理场强化去除技术

电场能改变矿物颗粒的表面电荷分布,通过促进它们之间的碰撞以及晶格破坏从而改变尾矿颗粒的物相结构,同时产生的氧泡会扰动反应体系进一步提高浸出浸出率[38,39,40]。超声波作为湿法冶金中辅助手段在矿石浸出过程中的应用越来越普遍,可归于机械效应、声空化和热效应的超声波能量照射能促进金属离子脱附解吸[41]。相同条件下,超声波浸出的金属比常规方法能增加20%,不仅有效缩短了浸出时间和药剂使用量,而且对有机结合态和残渣态有一定去除效果[42]。加热条件下能缩短重金属溶解时间,微波加热离子溶液的偶极旋转机制可以降低重金属浸出阻力,Yali Zhang[43]等采用微波-超声波辅助浸出方法,在超声波功率1000W、微波功率500W、温度95℃、氢氧化钠浓度150g/L的较优条件下,钒的浸出率可达90%以上。体系中重金属离子受到电场力后形成运动的带电粒子,在与两极垂直的磁场中会受洛伦兹力作用而引起液相旋转,改变了电解槽中的电流分布、电位分布和功率分布,从而引起阴极沉积方向的改变,有利于消除浓差极化现象,M Lovás通过微波强化磁选铜矿,磁选结束后锑、砷和汞的含量有明显降低[44]。

尾矿细颗粒对重金属有较强的吸附能力,热脱附、淋洗及电动处理等技术提供给污染物迁移的动力,但一般只作用于孔隙溶液中的污染物,对残渣态、铁锰氧化态、有机结合态等形态去除效率低。因此,电动-生物技术、电动-淋洗技术以及磁场、微波、超声波强化去除过程等联合优化重金属去除技术仍将是未来研究热点。

2尾矿及其资源化利用概况

大量尾矿堆存产生了一系列的社会、环境问题,由此对其重金属进行去除或稳定化处理后用于矿山空场充填[45]、建材生产[46]、生产高附加值材料[47]和再选回收[48]等资源化利用较为广泛,也有将其制备成肥料[49]、土壤改良剂[50]或通过加入具备促进物质能量循环的微生物、高有机质和含水量大的土壤改良剂改善尾矿理化性质而促进尾矿植被复垦[51]。

2.1矿山空场充填

以矿石采选尾砂、废石等为基料混合水泥、粉煤灰等胶凝剂制备成力学性能较好的充填体回填于矿山采空区,能最大限度地提高采矿工作安全性和降低尾矿库风险,对稳定地下空洞、提高矿石利用率和降低矿山修复成本方面有明显效果[52,53]。随着新型胶凝材料的研发,胶结膏体充填法在矿山充填中有广阔的应用前景,但其充填性能受尾矿初始含水率[54]、粒径分布[55]和胶凝材料占比[56]等影响较大。

2.2建材生产

尾矿尾砂主要是含SiO2、Al2O3、CaO、MgO和Fe2O3等化学成分的粉状物料,其组成与建材非常相似,Karhu等[57]研究了以钼、金、石英尾矿为原料开发莫来石基耐火陶瓷,XingdongLv等[58]研究发现,在水胶比0.45附近,尾矿配制的混凝土的抗压强度、轴向抗拉强度、极限拉应变和压缩弹性模量均远高于自然配制的混凝土,而且有更为优越的热性能。LiWeishi等[59]以细粒低硅铁矿尾矿为主要原料,水化硅酸钙凝胶和钙矾石作为粘结剂,一定条件下固化28d后成型砖的抗压强度和饱和抗压强度分别为27.2 MPa和24.3 MPa。此外,用金属尾矿辅以胶凝材料和一定的外加剂制备成免烧砖;以高硅尾矿为骨料,添加水泥和碱激发剂后经脱模切割和高温蒸养可制作成蒸养砖;富含SiO2、Al2O3、Fe2O3的金属尾矿添加一定的黏土即可进行高温烧结制成烧结砖。

2.3生产高附加值材料

沸石主要是由[SiO4]4-和[AlO4]5-四面体三维网状结构组成的具有微孔结构的纳米无机材料,具有吸附、离子交换和催化等优异性能,硅铝含量与沸石接近的尾矿制备成沸石是一种高附加值利用方法[60]。Zhendong Peng等[61]以天然低品位钼矿为原料,在水热合成过程中直接加入纳米氧化铁合成磁性沸石,吸附量高且稳定,理论最大吸附量达204.2mgCd/g。

2.4再选回收

随着高品位矿产的过度开采,冶金尾矿可以被认为是金属的二次来源,虽然已有许多关于尾矿有价金属提取的研究,但是开发环境友好的回收利用技术仍是必须解决的技难题。Haoyu Li等[62]从含金尾矿中氯化热处理后金回收率达85.99wt%,除氯率为82.84 wt%。

2.5土壤改良应用

众多研究表明尾矿在土壤方面的应用主要有制备元素肥料、土壤改良剂,在土壤系统功能改善方面具有巨大潜力。尾矿富含Zn、Cu、Mo、Cu、B、Fe等维持植物生长和发育所必需的元素,经适当处理后可加工成土壤改良剂或微量元素肥料,能够改善贫瘠土地营养状况,并且对土壤结构和酸碱性具有很好的改良效果[63]。Jing Mu等[64]以酸提铜尾矿残渣为原料,以残渣:CaO:Na2CO3:NaOH=1:0.4:0.4:0.2在550~1150℃下进行30分钟热活化后制备了硅铁改性剂,并通过土壤培养和温室盆栽试验发现该改良剂能有效降低重金属污染土壤中Cd、Cr、Pb有效性,促进了植物生长和根内Cd和Cr的积累。

3尾矿土壤化利用研究

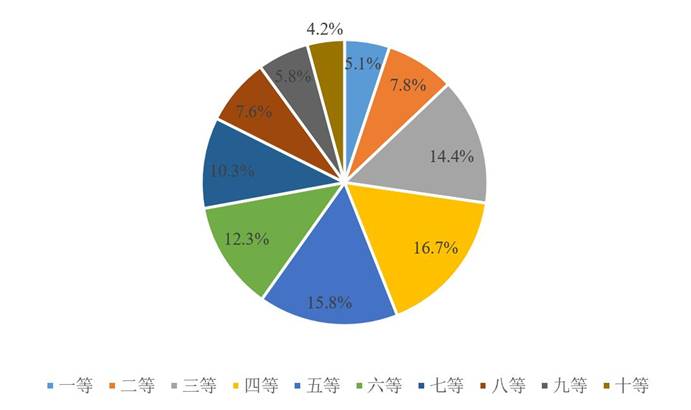

土壤是人类不可或缺的自然资源,虽然我国每年土壤污染防治投入不断增加,但是仍然面临水土流失严重、耕地质量平均等级偏低、土壤荒漠化和沙化严重等问题,此外,如图3所示,所调查的18.26亿亩耕地中,我国低等级的耕地质量占比较大。

图3 全国耕地质量等级比例

除了上述的土地退化外,全国工矿业中矿石冶炼及其尾矿堆积过程中Cu、As、Mn、Zn、Cr、Hg等物质的迁移转化易产生不同程度的环境污染,常使周围土壤重金属含量远高于背景值[65]。对全国193个城市规划区土壤中微量元素的系统研究表明,已有22个城市规划区土壤已达到重度污染,5个城市规划区土壤暴露对未成年人具有潜在风险,其污染元素以Cd、Hg、Se等重金属为主,在以潜在酸性较强的喀斯特地貌和红壤为主的西南地区尤为严重[66,67]。此外,我国矿山和重金属污染场地生态修复中常使用的去除或更换表土方法存在客土土源供给不足、工程量大、投资高等问题[68]。

去除重金属后的尾矿是潜在的土壤源。以清洁或农用土壤相关的有机质、水分、容重、团粒结构以及矿物质为目标,通过添加改性材料改善尾矿理化性质和稳定重金属使其满足相关用土标准进而实现土壤化利用,对促进尾矿资源化利用和缓解土源压力具有重要意义。

有机废物及工业废物对尾矿土壤形成有积极的影响,施用后能有效改善尾矿总有机碳含量低的问题,调节合适的pH能促进有机-矿石复合物颗粒的形成,加速土壤生态系统功能的建立和恢复[69]。T. Pardo[70]等将猪粪堆肥联合熟石灰混合到矿山类尾矿土壤中,溶解性有机碳和NKP明显增加并在竖直方向上产生了一定的位移,其pH和氧化还原条件变化成功地降低了金属的流动性,相关的浸出风险有所减少。他们的进一步研究表明改良剂降低了尾矿土相关风险,提供的养分促进了植物生长,并显著增加了土壤酶活性[71]。Shenggao Lu等[72]对类尾矿土壤长期施用化肥和猪粪,增大了孔隙率,Dai H等[73]在其它施肥量相等的条件下,采用秸秆、沼渣、有机肥和生物炭进行大田试验,土壤有机碳含量和团聚体稳定性显著改善,表明秸秆和畜禽粪便等有机废物对改善尾矿理化性质方面有很大价值。

有机废物除了对尾矿营养条件、孔隙率、团粒结构等理化性质改善明显外,在重金属稳定化和增加土壤生物多样性等方面也发挥着重要作用。Mehboob Alam等[74]选取铬矿、石英矿、锰矿等矿堆土壤,将蚯蚓粪、园林土、矿堆土壤按1:1:1比例混合培育后,Cd、Cr、Pb和Mn浸出量分别减少了32.5%、50.25%、44.50%和42.25%,并且降低了重金属的生物有效性,同时也有研究表明添加蚯蚓粪能促进尾矿作物植物中粗大根的生长,增大了植物对尾矿重金属、高密度和酸碱度等理化基质的抗逆性[75]。P. Abad-Valle等[76]用橄榄固废、城市固废堆肥、褐煤和泥炭添加到矿山类尾矿土壤中,可移动锌镉含量的减量效果明显,而且土壤呼吸、酶活性都有明显提高,对土壤微生物功能建立和恢复有较好效果。

尾矿土壤化利用过程中除了添加有机废物外,还常常使用生物炭、碱性或盐类无机材料。生物炭在尾矿土壤化中具有普遍适用性,具有很高的碳含量和稳定性,可以用于尾矿长期固碳,生物炭添后能提高尾矿微生物酶活性和植物苗初期生长,降低植物对重金属吸收[77,78]。一般情况下,向尾矿中添加石灰能调节pH,但有研究表明石灰添加后尾矿中锑更溶易浸出,之后的尾矿土壤化利用应该在一定程度上限制石灰的添加并进行长期试验[79,80]。在土壤化过程中微生物群落的建立是不可或缺内容,重金属污染可以通过影响微生物生物量、多样性和土壤酶活性来降低土壤微生物碳矿化和硝化作用[81]。此外,与植物根系相关的一些根际微生物群落除了自身的相互作用外,还会与植物发生相互作用,通过接种根际微生物或者施加有机肥能显著降低植物根际重金属有效性,提高土壤活性[82]。

4结语

资源-产品-废弃尾矿发展模式带来的生态环境风险和土地资源浪费给农业安全带来了极大的压力。在越来越高的环保要求下,传统的填埋和建尾矿库堆存的处理处置方式难以满足污染控制和资源循环利用的可持续发展要求,虽已进行大量矿山空场充填、建材生产、生产高附加值材料及再选回收等方面的资源再利用,但受尾矿物性复杂多变、重金属含量高、生产工艺复杂和社会可接受度低等限制,现阶段我国尾矿仍存在综合利用率低和堆存量不断增加的问题。与此同时,我国即使每年增加土壤污染防治投入,但仍然面临土地质量差、水土流失量大、土壤荒漠化和沙化严重等问题。目前已在传统的重金属污染土壤修复技术的基础上研究出许多对尾矿有价金属提取及重金属去除的有关技术,并进行了多种联合优化去除技术的研究,但仍缺乏尾矿重金属高效去除方法研究,难以控制资源化利用过程中重金属迁移转化行为。

因此,将去除重金属的尾矿进行改性后制备成符合相关标准和使用要求的土壤以实现尾矿土壤化利用,可从根本上解决尾矿大量堆存、有机固废利用率低等问题,也为解决农用地及矿山用土环境质量差、资源不足等问题提供新途径,对加强污染防治和绿色矿山建设,持续改善环境质量,坚持可持续发展具有重要意义。

参考文献

[1] 郭娟,崔荣国,闫卫东,林博磊,马建明,刘增洁,周起忠.2020年中国矿产资源形势回顾与展望[J].中国矿业,2021,30(01):5-10+54.

[2] 侯攀,陈宇清,樊宇姣.金属矿山尾矿综合利用现状[J].现代矿业,2017, 33(02): 129-131.

[3] 刘玉林,刘长淼,刘红召,等.我国矿山尾矿利用技术及开发利用建议[J].矿产保护与利用,2018(06):140-144+150.

[4] Xufeng Fei, George Christakos, Rui Xiao, et al. Improved heavy metal mapping and pollution source apportionment in Shanghai City soils using auxiliary information[J]. Science of the Total Environment,2019,661.

[5] Cheng Zhao, Yan Dong, Yupeng Feng, Yuzhong Li, Yong Dong. Thermal desorption for remediation of contaminated soil: A review[J]. Chemosphere,2019,221.

[6] Jingzi Beiyuan, Abbe Y.T.Lau, Daniel C.W.Tsang, et al. Chelant-enhanced washing of CCA-contaminated soil: Coupled with selective dissolution or soil stabilization[J]. Science of the Total Environment,2018,612.

[7] Wang Yuchen, Li Ang, Cui Chongwei. Remediation of heavy metal-contaminated soils by electrokinetic technology: Mechanisms and applicability[J]. Chemosphere,2021,265.

[8] Parisa Chegounian,Hisham Zerriffi,Vikramaditya G. Yadav. Engineering Microbes for Remediation of Oil Sands Tailings[J]. Trends in Biotechnology,2020.

[9] Li M S. Ecological restoration of mineland with particular reference to the metalliferous mine wasteland in China: A review of research and practice.[J]. The Science of the total environment,2006,357(1-3).

[10] Titshall, Louis W., Hughes, Jeffrey C.,Bester, H. Christopher. Characterisation of alkaline tailings from a lead/zinc mine in South Africa and evaluation of their revegetation potential using five indigenous grass species[J]. South African Journal of Plant and Soil,2013,30(2).

[11] 熊佳.重金属在锑尾矿库尾砂剖面上的迁移过程研究、周边土壤重金属来源分析及污染状况评价[D].贵州大学,2020.

[12] Zhiyou Fu, Fengchang Wu, Changli Mo, et al. Comparison of arsenic and antimony biogeochemical behavior in water, soil and tailings from Xikuangshan, China[J]. Science of the Total Environment,2016,539.

[13] Adator Stephanie Worlanyo, Li Jiangfeng. Evaluating the environmental and economic impact of mining for post-mined land restoration and land-use: A review[J]. Journal of Environmental Management, 2020, 111623.

[14] Gordon M. Ritcey. Tailings management in gold plants[J]. Hydrometallurgy, 2005,78(1).

[15] 张家荣,刘建林.中国尾矿库溃坝与泄露事故统计及成因分析[J].中国钼业,2019, 43(04):10-14.

[16] 冯治勤. 同频共振,共克时艰—关于应对甘肃陇南锑泄漏事件的回顾与思考[J]. 中国环境监察, 2016, 000(007): 62-66.

[17] F. Guo, F. C. Wu, F. Yu, et al. Fate and removal of antimony in response to stringent control activities after a mine tailing spill[J]. Science of the Total Environment,2019,693.

[18] Macêdo Anderson Kelvin Saraiva, Santos Keiza Priscila Enes dos, Brighenti Ludmila Silva, et al. Histological and molecular changes in gill and liver of fish (Astyanax lacustris Lütken, 1875) exposed to water from the Doce basin after the rupture of a mining tailings dam in Mariana, MG, Brazil[J]. Science of the Total Environment,

[19] 生态环境部.全国大中城市固体废物污染环境防治年报[EB/OL]. http://www.mee.gov.cn/hjzl/sthjzk/gtfwwrfz/, 2020-12-28.

[20] Troxler W, Cudahy J, Zink R, Yezzijr J, Rosenthal S. Treatment ofnonhazardous petroleum-contaminated soils by thermal desorption technologies[J]. Air Repair, 1993, 1512-1525.

[21] Woo Rim Lee,Yujin Eom,Tai Gyu Lee. Mercury recovery from mercury-containing wastes using a vacuum thermal desorption system[J]. Waste Management,2017,60.

[22] Yanyan Gong, Dongye Zhao, Qilin Wang. An overview of field-scale studies on remediation of soil contaminated with heavy metals and metalloids: Technical progress over the last decade[J]. Water Research,2018.

[23] Ilwon Ko, Yoon-Young Chang, Cheol-Hyo Lee,Kyoung-Woong Kim. Assessment of pilot-scale acid washing of soil contaminated with As, Zn and Ni using the BCR three-step sequential extraction[J]. Journal of Hazardous Materials,2005,127(1).

[24] Eun Hea Jho, Jinwoo Im, Kyung Yang, et al. Changes in soil toxicity by phosphate-aided soil washing: Effect of soil characteristics, chemical forms of arsenic, and cations in washing solutions[J]. Chemosphere,2015,119.

[25] Xin Ke, Feijie Zhang, Yan Zhou, et al. Removal of Cd, Pb, Zn, Cu in smelter soil by citric acid leaching[J]. Chemosphere,2020,255.

[26] Fenghui Wu, Chenyang Zhao, Guangfei Qu, et al. Adsorption of Arsenic From Aqueous Solution Using Zero-valent Iron Material Modified by Ionic liquid of [Hmim]SbF6[J]. RSC Advances, 2021, 11, 6577 - 6585

[27] Weijin Feng, Shirong Zhang, Qinmei Zhong, et al. Soil washing remediation of heavy metal from contaminated soil with EDTMP and PAA: Properties, optimization, and risk assessment[J]. Journal of Hazardous Materials,2020,381.

[28] Xiaofang Guo, Guohui Zhao, Guixiang Zhang, et al. Effect of mixed chelators of EDTA, GLDA, and citric acid on bioavailability of residual heavy metals in soils and soil properties[J]. Chemosphere,2018,209.

[29] Ortiz-Soto Rodrigo, Leal Daniela, Gutierrez Claudia, et al. Electrokinetic remediation of manganese and zinc in copper mine tailings.[J]. Journal of hazardous materials,2019,365.

[30] Cameselle, Claudio. Enhancement Of Electro-Osmotic Flow During The Electrokinetic Treatment Of A Contaminated Soil[J]. Electrochimica Acta, 2015, 181:31-38.

[31] Sun T R, Ottosen L M, Jensen P E, et al. Effect of pulse current on acidification and removal of Cu, Cd, and As during suspended electrodialytic soil remediation[J]. Electrochimica Acta, 2013, 107(3):187-193.

[32] Lizhu Yuan, Xingjian Xu, Haiyan Li, Quanying Wang, et al. The influence of macroelements on energy consumption during periodic power electrokinetic remediation of heavy metals contaminated black soil[J]. Electrochimica Acta,2017,235.

[33] Babu A G, Shim J, Bang K S, et al. Trichoderma virens PDR-28: a heavy metal-tolerant and plant growth-promoting fungus for remediation and bioenergy crop production on mine tailing soil[J]. Journal of Environmental Management, 2014, 132:129-134.

[34] Jie Li, Qian Wang, Shengzhe Zhang, et al. Phylogenetic and genome analyses of antimony-oxidizing bacteria isolated from antimony mined soil[J]. International Biodeterioration & Biodegradation,2013,76.

[35] Van, KhanhNguyen, WonyoungChoi, et al. Microbial oxidation of antimonite and arsenite by bacteria isolated from antimony-contaminated soils[J]. International Journal of Hydrogen Energy, 2017.

[36] Rizwan M, El-Shamy M, Abdel-Aziz H M. Assessment of trace element and macronutrient accumulation capacity of two native plant species in three different Egyptian mine areas for remediation of contaminated soils[J]. Ecological Indicators, 2019, 106.

[37] Pérez Rodrigo, Tapia Yasna, Antilén Monica, et al. Interactive effect of compost application and inoculation with the fungus Claroideoglomus claroideum in Oenothera picensis plants growing in mine tailings[J]. Ecotoxicology and Environmental Safety,2021,208.

[38] Luo Zhenggang, Shu Jiancheng, Chen Mengjun, et al. Enhanced leaching of manganese from low-grade pyrolusite using ball milling and electric field[J]. Ecotoxicology and Environmental Safety,2021,211.

[39] Liu, Z., Nueraihemaiti, A., Chen, M., Du, J., Fan, X., Tao, C., 2015. Hydrometallurgical leaching process intensified by an electric field for converter vanadium slag. Hydrometallurgy 155, 56–60

[40] Deng Rongrui, Xie Zhaoming, Liu Zuohua, Tao Changyuan. Leaching kinetics of vanadium catalyzed by electric field coupling with sodium persulfate[J]. Journal of Electroanalytical Chemistry,2019,854.

[41] A.Fraiese, A.Cesaro, V. Belgiorno, et al. Ultrasonic processes for the advanced remediation of contaminated sediments[J]. Ultrasonics Sonochemistry,2020,67.

[42] Libo Zhang, Wenqian Guo, Jinhui Peng, et al. Comparison of ultrasonic-assisted and regular leaching of germanium from by-product of zinc metallurgy[J]. Ultrasonics - Sonochemistry,2016,31.

[43] Yali Zhang, Xia Chen, Wei Chu, et al. Removal of vanadium from petroleum coke by microwave and ultrasonic-assisted leaching[J].Hydrometallurgy, 2020,191.

[44] M Lovás, I Murová, A Mockovciaková, N Rowson,Š Jakabský. Intensification of magnetic separation and leaching of Cu-ores by microwave radiation[J]. Separation and Purification Technology,2003,31(3).

[45] Chongchong Qi, Andy Fourie. Cemented paste backfill for mineral tailings management: Review and future perspectives[J]. Minerals Engineering,2019,144.

[46] Li Weishi, Lei Guoyuan, Xu Ya, Huang Qifei. The properties and formation mechanisms of eco-friendly brick building materials fabricated from low-silicon iron ore tailings[J]. Journal of Cleaner Production,2018,204.

[47] Juliana de Carvalho Izidoro, Michelle Caroline Kim, Valentina Ferraraccio Bellelli, Mara Cristina Pane, Jorge Alberto Soares Tenório, et al. Synthesis of zeolite A using the waste of iron mine tailings dam and its application for industrial effluent treatment[J]. Journal of Sustainable Mining,2019,18(4).

[48] Zhidong Tang, Peng Gao, Yanjun Li, et al. Recovery of iron from hazardous tailings using fluidized roasting coupling technology[J]. Powder Technology, 2020,361.

[49] Tan Yonghao, Zou Zhemin, Qu Jun, Ren Jie, Wu Chenjie, Xu Zhigao. Mechanochemical conversion of chrysotile asbestos tailing into struvite for full elements utilization as citric-acid soluble fertilizer[J]. Journal of Cleaner Production,2021,283.

[50] Sang-Hwan Lee, Eui Young Kim, Hyun Park, Jihoon Yun, Jeong-Gyu Kim. In situ stabilization of arsenic and metal-contaminated agricultural soil using industrial by-products[J]. Geoderma,2010,161(1).

[51] 李敏.铁尾矿土壤化利用过程中重金属污染的植物修复和土壤改良技术[D].山东大学,2017.

[52] Deng D Q, Liu L, Yao Z L, et al. A practice of ultra-fine tailings disposal as filling material in a gold mine [J]. Journal of environmental management,2017,196.

[53] 刘浪,方治余,张波,等.矿山充填技术的演进历程与基本类别[J/OL].金属矿山:1-13[2021-03-13]. http://kns.cnki.net/kcms/detail/34.1055.td.20210125.1340.002.html.

[54] Mohammadamin Jafari, Mohammad Shahsavari, Murray Grabinsky. Experimental Study of the Behavior of Cemented Paste Backfill under High Isotropic Compression[J]. Journal of Geotechnical and Geoenvironmental Engineering,2020,146(11).

[55] Jiangyu Wu, Meimei Feng, Zhanqing Chen, et al. Particle Size Distribution Effects on the Strength Characteristic of Cemented Paste Backfill[J]. Minerals,2018,8(8).

[56] Yue Zhao, Amin Soltani, Abbas Taheri, et al. Application of Slag–Cement and Fly Ash for Strength Development in Cemented Paste Backfills[J]. Minerals,2018,9(1).

[57] Marjaana Karhu, Juha Lagerbom, Soili Solismaa, et al. Mining tailings as raw materials for reaction-sintered aluminosilicate ceramics: effect of mineralogical composition on microstructure and properties[J]. Ceramics International,2018,45(4).

[58] Xingdong Lv, Weiguo Shen, Lei Wang, et al. A comparative study on the practical utilization of iron tailings as a complete replacement of normal aggregates in dam concrete with different gradation[J]. Journal of Cleaner Production,2019,211.

[59] Li Weishi, Lei Guoyuan, Xu Ya, Huang Qifei. The properties and formation mechanisms of eco-friendly brick building materials fabricated from low-silicon iron ore tailings[J]. Journal of Cleaner Production,2018,204.

[60] Zhiqin Qiang, Xianjiang Shen, Min Guo, Fangqin Cheng, Mei Zhang. A simple hydrothermal synthesis of zeolite X from bauxite tailings for highly efficient adsorbing CO 2 at room temperature[J]. Microporous and Mesoporous Materials,2019,287.

[61] Peng Zhen-dong, Lin Xue-ming, Zhang Yu-long, et al. Removal of cadmium from wastewater by magnetic zeolite synthesized from natural, low-grade molybdenum[J]. Science of the Total Environment,2021,772.

[62] Li Haoyu, Peng Jinhui ,Long Hailin, Li Shiwei,Z hang Libo. Cleaner process: Efficacy of chlorine in the recycling of gold from gold-containing tailings[J]. Journal of Cleaner Production,2020(prepublish).

[63] A. Zanuzzi, J.M. Arocena, J.M. van Mourik, A. Faz Cano. Amendments with organic and industrial wastes stimulate soil formation in mine tailings as revealed by micromorphology[J]. Geoderma,2009,154(1).

[64] Jing Mu, Zhengyi Hu, Lijuan Huang, Zijian Xie, Peter E. Holm. Preparation of a silicon-iron amendment from acid-extracted copper tailings for remediating multi-metal-contaminated soils[J]. Environmental Pollution,2020,257.

[65] Xuejun Guo, Kunpeng Wang, Mengchang He, et al. Antimony smelting process generating solid wastes and dust:Characterization and leaching behaviors[J]. Journal of Environmental Sciences,2014,26(07):1549-1556.

[66] 李括,彭敏,杨峥,等.中国193个城市规划区土壤微量元素污染与健康风险[J].环境科学,2020,41(04):1825-1837.

[67] 龙健.我国南方红壤矿区复垦土壤微生物生态特征及其恢复研究[D].浙江大学,2004.

[68] 张先昂.矿山生态修复及模式选择[J].现代矿业,2020,36(10):228-229.

[69] A. Zanuzzi, J.M. Arocena, J.M. van Mourik, A. Faz Cano. Amendments with organic and industrial wastes stimulate soil formation in mine tailings as revealed by micromorphology[J]. Geoderma,2009,154(1).

[70] Pardo T, Bernal M P, Clemente R. Efficiency of soil organic and inorganic amendments on the remediation of a contaminated mine soil: I. Effects on trace elements and nutrients solubility and leaching risk[J]. Chemosphere, 2014, 107:121-128.

[71] Pardo T, Clemente R, Alvarenga P, et al. Efficiency of soil organic and inorganic amendments on the remediation of a contaminated mine soil: II. Biological and ecotoxicological evaluation[J]. Chemosphere, 2014, 107:101-108.

[72] Shenggao Lu, Xiuling Yu, Yutong Zong. Nano-microscale porosity and pore size distribution in aggregates of paddy soil as affected by long-term mineral and organic fertilization under rice-wheat cropping system[J]. Soil and Tillage Research, 2019, 186:191-199.

[73] Dai H , Chen Y , Liu K , et al. Water-stable aggregates and carbon accumulation in barren sandy soil depend on organic amendment method: A three-year field study[J]. Journal of Cleaner Production, 2019, 212:393-400.

[74] Mehboob Alam, Zawar Hussain, Anwarzeb Khan, et al. The effects of organic amendments on heavy metals bioavailability in mine impacted soil and associated human health risk[J]. Scientia Horticulturae, 2019, 262.

[75] Gisele de Fátima Esteves, Kamila Rezende Dázio de Souza, Leticia Aparecida Bressanin, et al. Vermicompost improves maize, millet and sorghum growth in iron mine tailings[J]. Journal of Environmental Management,2020,264.

[76] Abad-Valle P, Iglesias-Jimenez E, Alvarez-Ayuso E. A comparative study on the influence of different organic amendments on trace element mobility and microbial functionality of a polluted mine soil[J]. Journal of Environmental Management, 2017, 188:287-296.

[77] Amoah-Antwi C, Kwiatkowska-Malina J, Thornton S F, et al. Restoration of soil quality using biochar and brown coal waste: A review[J]. Science of The Total Environment, 2020, 722:137852.

[78] AZ Khan, S Khan, T Ayaz, et al. Popular wood and sugarcane bagasse biochars reduced uptake of chromium and lead by lettuce from mine-contaminated soil[J]. Environmental Pollution, 263.

[79] Lydie Le Forestier, Mikael Motelica-Heino, Philippe Le Coustumer, Michel Mench. Phytostabilisation of a copper contaminated topsoil aided by basic slags: assessment of Cu mobility and phytoavailability[J]. Journal of Soils and Sediments,2017,17(5).

[80] Susan C. Wilson, Calvin D. Leech, Leo Butler, et al. Effects of nutrient and lime additions in mine site rehabilitation strategies on the accumulation of antimony and arsenic by native Australian plants[J]. Journal of Hazardous Materials,2013,261.

[81] Huang Yu, Xiafei Zheng, Wanlin Weng, et al. Synergistic effects of antimony and arsenic contaminations on bacterial, archaeal and fungal communities in the rhizosphere of Miscanthus sinensis: Insights for nitrification and carbon mineralization[J]. Journal of Hazardous Materials, 2021, 411.

[82] Pérez Rodrigo, Tapia Yasna, Antilén Monica, et al. Interactive effect of compost application and inoculation with the fungus Claroideoglomus claroideum in Oenothera picensis plants growing in mine tailings[J]. Ecotoxicology and Environmental Safety, 2021, 208.