引 言

磷石膏是磷化工企业产生的一种主要固体废弃物之一,大约每生产1 吨的磷酸产物就会产生4.5~6.5吨的磷石膏[1,2];据不完全统计,磷石膏的全球年产量已经高达300公t[3],而能被资源化利用的只占总量的15% [4]左右;2016年我国磷化工产业副产磷石膏的量就达到了7600万t,而能被综合利用的只有2700万吨左右,利用率不到27% [5]。我国磷石膏的目前累积堆存量已经远远超过了5亿t[6],并且以4000万吨/年的速率在增加,磷石膏的堆存不仅会占用大面积的土地资源,而且存放在尾矿库中还会对周边环境造成很大的潜在危险性[2,7]。磷石膏合理有效地资源化利用问题严重制约了磷化工企业的发展,但随着国家和社会对磷石膏问题的广泛关注,在磷石膏资源化利用方面的研究也越来越多,如利用磷石膏制备高强石膏[8,9]、二氧化硫[10]、土壤改良剂[1]、温室气体吸收材料[11]、建筑材料[12-15]、路基材料[16]以及一些特殊性能材料[17-20]等,还有部分专家学者对磷石膏中的稀贵重金属也进行了研究[21,22]。针对目前磷石膏的资源化利用现状,达到磷石膏高附加值利用率的目的,解决磷石膏基产品所携带物质的潜在危害性,这些都成为了研究磷石膏资源化利用途径的必然趋势。

随着国家、社会以及专家学者的辛劳付出,发现了双极膜技术也许能真正实现磷石膏全方位、多层次的资源化利用,实现材料的多循环、污染的零排放[23]。双极性膜电渗析方法的是利用电化学结合膜分离原理实现三废资源化利用、零排放的一种有效的废物处理方法。由于该技术的应用还处于实验室规模或发展的早期阶段[24],其在工业上大规模应用还是难以实现的;除此,该技术能耗较高[25]等缺陷也严重制约了其发展运用。双极膜电渗析(BMED)具有对环境友好、能结合实际切实可行的优点,可将盐溶液转化为某种酸或碱[26],因此,在某些工业和环境治理领域也有一定的应用,如磷酸盐回收[27]、CO2捕获[28]、纺织废水中回收资源[29]、生产高碱度多铁硫酸盐[30]、从NaCl盐水中生产NaOH和HCl [31-33]、回收不同的有机酸[34-36]、原位修复铝土矿残渣[37]和工业盐水脱盐[38-40]。本文将磷石膏的资源化处理现状与双极膜的应用现状相结合,探讨双极膜在磷石膏资源化处理以及循环利用中的应用前景,为双极膜在磷石膏高附加值利用和污染零排放提供理论支撑。

1 磷石膏的资源化利用现状

由于受到技术、经济等方面因素的制约,磷石膏的综合利用率极低,这也就成为了制约磷化工产业发展的主要因素之一。国家生态环保部为了减少水土流失和避免环境遭到破坏,在2005年就采取了限制开采天然石膏储量的措施,由此加大了众多学者对于天然石膏性质和成分相似的磷石膏进行研究,但至今尚未取得在经济上较为可行的资源化综合利用方法,众多的研究方法由于成本太高,只能停留在实验室阶段,而不能在工业上应用[41]。而随着社会的发展,国家对环境问题是越来越重视,磷石膏的资源化、无害化综合利用迫在眉睫。针对全球磷化工企业面临将磷石膏无害化、资源化处理的共同难题,国内外众多专家和学者对磷石膏的资源化综合利用已经提出了二十多种方法/工艺,但总体来说,除了用作水泥缓凝剂、石膏砖以及路基材料等附加价值不是很高的领域外,在精细化工等高附加值产品中的应用较少,大多数研究会因为成本太高而得不到工业化应用[42,43]。目前,磷石膏的资源化综合利用途径总体上主要分为两类:一是预先净化处理后再利用[44],直接用作原料,操作简单,应用成本较低,但产品附加值较低,需求也较少,很难被大规模应用[45]。二是通过化学方法将其转化为产品附加值较高的化工原料,虽然此方法对磷石膏的需求很大,但成本太高,无法大范围应用 [46,47]。

1.1 磷石膏现状及基本性质

一般工业磷石膏呈灰白色或灰黑色,主要成分是CaSO4·2H2O[48]。虽然磷石膏的综合利用途径较多,但因含有可溶磷氟、重金属[49]、有机物以及微量放射性物质[50-52]等,使其综合利用率不到30%,大部分的磷石膏只能露天堆存,而这种长期露天处置的方法容易造成磷石膏中的氟化物、游离酸、有机物、有害重金属等有害物质随渗滤液流出,在一定程度上污染了土地资源和水资源,破坏生态环境平衡,环保压力与经济效益压力促使磷石膏资源化综合利用加快升级。磷石膏中70%以上为CaSO4·2H2O,并含有少量石英、金刚砂、铁粉、石灰、重金属、未分解的磷矿粉、含氟杂质、含酸杂质、放射性物质等杂质,表1列出了工业磷石膏中主要杂质种类及其存在形式。

表1 磷石膏中的杂质种类及存在形式

Table 1 Types and forms of impurities in phosphogypsum

杂质种类 |

主要存在形式 |

溶解性能 |

磷酸、磷酸盐 |

H2PO4、H2PO4-、HPO42-、CaHPO4·2H2O磷灰石、磷酸盐络合物[53,54] |

可溶、共晶体、难溶 |

氟化物 |

NaF、CaF2、CaSiF6、Na2SiF6[53,54] |

可溶、难溶 |

有机物 |

腐烂植物有机质、酸解催化有机添加剂 |

难溶 |

放射性物质 |

Ra、Th等 |

难溶 |

重金属 |

Cd、Cu、Zn、Pb、As、Hg、Al、Fe[55,56]等 |

难溶 |

磷石膏经加工提纯后呈白色粉末状,是结晶性能良好的单斜晶系柱状、四边形、燕尾状晶体。而工业副产的磷石膏中杂质含量比较多,一般为浅灰、浅黄或灰黑色粉末,W(H2O)约为25 %,密度在0.73~0.88 g/cm3,难溶于水,流动性能较差。磷石膏中含有的化学组分比较复杂,不同工艺、磷矿、企业产生的磷石膏所含的杂质种类及含量也各不相同,杂质的掺杂使得磷石膏粒径呈较为集中的正态分布并表现出弱酸性。高强度、高韧性的磷石膏不溶于常见的酸、碱,并且耐受高温,改性处理后与聚合物亲和力强,可用于加工生产复合材料[57]。

1.2 磷石膏资源化研究现状分析

磷石膏巨大产排量与有限利用量的矛盾仍未得到缓解,这也就要求科研学者要努力寻求创新理念,攻克技术难题。表2例举出了我国磷石膏资源化综合利用的主要应用领域,主要还是集中在建材行业以及工农业:

表2 磷石膏资源化利用领域

Table 2 Fields of resource utilization of phosphogypsum

应用领域 |

产品名称 |

建筑材料[14] |

石膏砌块[58]、石膏粉、水泥砂浆[59,60]、石膏板[61]、高强石膏[62-64] |

环境领域 |

吸附材料[65]、重金属固化剂、稳定剂[48]、温室气体吸收剂[66,67] |

化工原料 |

硫酸钙晶须、硫酸铵、缓凝剂、膨胀剂、硫酸、硫酸钾[68]、碳酸钙[69] |

农业生产 |

土壤改良剂[52,70]、硫肥、钙肥、硅肥、磷肥、钾肥[71] |

土工建材 |

吸声材料[65,72]、路基材料[75,76]、免烧砖[77,78]、泡沫材料[77]、防水材料[78] |

其他 |

填充材料[79,80]、日用化工、饲料添加剂、建筑艺术、装饰材料、稀贵重金属[81-83] |

近些年来,磷石膏的增长率和堆存率是越来越大,国家对环境保护的重视程度也是日益递增,针对磷石膏综合利用率极低的现象,我国目前已经取得了一些显著的成效,但也存在着一些无法解决的问题,如:

(1)磷资源区域间的发展不平衡。我国磷矿资源主要分布于云南、四川、贵州、湖北、安徽等地区,这些地区的磷石膏产量占全国磷石膏总产量的75%以上,大多数磷化工企业处地偏远地区,远离石膏需求地,受地域和运输成本的影响,严重制约了磷石膏资源化综合利用的经济效益。

(2)磷石膏成分复杂多变,无法在工业中大规模应用。受地区、工艺、原料等因素的影响,磷石膏中杂质的种类、含量及其赋存形态存在较大的差异,同一种磷石膏资源化综合利用流程对某一地区的磷石膏效果会较好,但在其他地区未必也能达到下相同的效果。

(3)我国在磷石膏方面设定的标准体系不完善。目前虽然也出台了与磷石膏相关的政策性文件,但由于受传统观念的影响,大众依旧认为磷石膏就是一种固体废物,其制得的相关产品依旧存在某些危害性,因此磷石膏相关产品不为市场所接受,这也大大限制了磷石膏的资源化综合利用。

(4)针对磷石膏处理处置方面的法律法规、标准等文件协同度不高。一方面,许多磷化工企业存在侥幸心理,他们试图寻找法律的漏洞,不愿在磷石膏的后续处理与处置中进行耗资耗力;另一方面,对磷石膏针对性、集中性处理与处置的企业较少,磷石膏的后续化处理需要耗费大量时间、精力、金钱,大型企业可能会重视磷石膏的后续处理,但对于大部分的中小型企业来说自身的利益最重要。

2 双极膜的运用现状

近几年来,因双极膜所具的独特性能,研究人员对其的研究越来越多[84]。双极膜是由阳离子交换层(N型膜)、界面亲水层(催化层)和阴离子交换层(P型膜)所组成的一种新型离子交换复合膜 [85,86]。对双极膜电渗析技术的研究最早追溯到20世纪50年代中叶,到80年代中期时,膜合成制备技术、工作过程及机理研究等方面已经取得了一些研究进展,在环境污染控制、二次资源回收、化学化工过程、盐水水解技术等领域中都开展了实验探究,并充分展现出双极膜技术的优越性。双极膜电渗析技术的引进,对环境、化工、能源等领域的传统工艺的改进以及新工业过程的设计起到了至关重要的推进作用,特别是在海水淡化和制盐领域,一直保持15%左右的增长率[87],但一直存在应用方向单一的问题,仅仅在海水脱盐[88]和超纯水制备方面已有小规模的应用[89,90],除此之外,其在清洁生产和循环利用中的作用也日益突出[86],所以实现该技术应用的工业化以及发展新兴的应用领域非常必要。

2.1 双极膜电渗析技术在酸碱再生过程中的应用

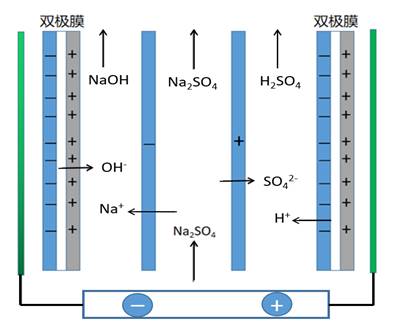

硫酸钠的再生过程是以纯化了的结晶态硫酸钠作三隔室电渗析池中的原料盐,经过双极膜作用,可将其转化为碱(NaOH)和酸(H2SO4、HCl)[91,92]。图1展示了硫酸钠制酸和碱的一个作用示意图,如图所示:在该过程中水可用于生成清洁的碱溶液,该溶液可以重新被利用,而中间槽液(含质量分数15%~20%的Na2SO4和质量分数为6%~8%的H2SO4)循环流过右酸室来收集生成的酸,这样大量酸(H2SO4)的迁移进入强化了中间槽的酸度[93],也较少了整个工艺的耗水量,并能将电流效率保持在较高的水平[94]。

图1硫酸钠制酸和碱

Fig.1 Sodium sulfate to make acids and bases

2.2 双极膜技术在有机酸碱生产中的应用

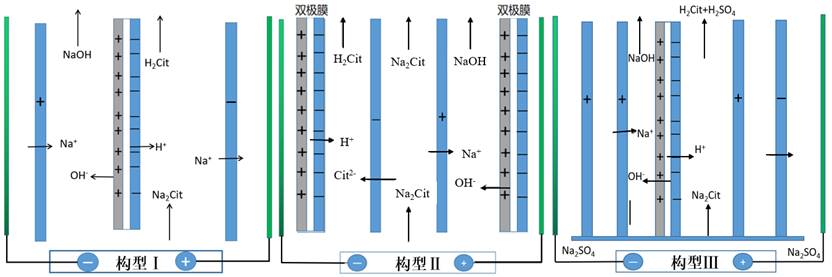

徐铜文[95]等人研究了双极膜电渗析技术在柠檬酸生产工艺中的影响机制,并考察了不同浓度的柠檬酸钠对整个工艺过程、综合能耗、电流效率等指标的影响,得出双极膜电渗析生产柠檬酸浓度最佳时的柠檬酸钠浓度在0.5~1.0 M左右。该实验同时对A-C-BP-A-C(构型I)、C-BP-C(构型 II)和BP-A-C-BP(构型III)三种不同的膜堆混合结构对生产柠檬酸的浓度进行了比较(如图2所示)。考察膜堆的电压、电流效率和能耗大小等因素,这三种膜堆结构对柠檬酸产生量的影响顺序为:构型II<构型I<构型III。三个种不同膜堆构型的双极膜两端的电势差影响的大小顺序为:构型 II>构型I≈构型III。构型II是这三种构型中最合适的构型,而构型III是最不经济的构型[96]。

图2 双极膜的不同应用类型

Fig.2 Different application types of bipolar membranes

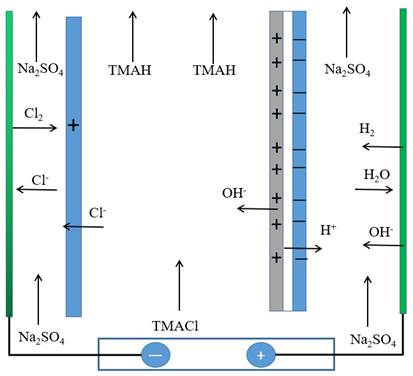

徐铜文[97]等人还研究了双极膜电渗析法对四甲基氢氧化铵生产过程的影响,整个过程采用A-BP(A:阴离子交换膜;BP:双极膜)的膜堆构型(如图3所示),水解离产生的氢氧根取代了四甲基铵根离子,再经过电碱化作用,生成四甲基氢氧化铵。实验结果表明:电流效率与盐浓度呈正相关、与电流密度呈负相关,能耗与盐浓度呈负相关、与电流密度呈正相关,能耗最低为1.43 kWh·Kg-1。整个研究也表明用双极膜电渗析法制备四甲基氢氧化铵可将整体的成本控制在0.33 $·Kg-1左右,达到成本低、无二次污染的目的。

图3 双极膜电渗析技术生产甲基氢氧化铵

Fig.3 Production of methyl ammonium hydroxide by bipolar membrane electrodialysis technology

2.3 双极膜技术在脱除烟气中SO2过程中的应用

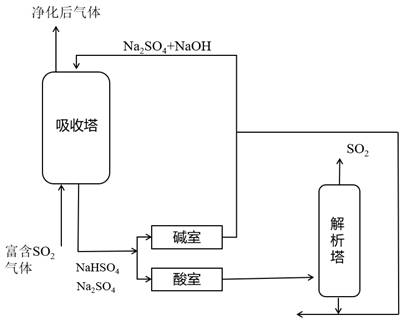

化工厂、发电厂、冶金厂在燃烧过程中会释放出大量的酸性气体[98],以硫化物为例,我国各企业在燃煤燃油过程中会产生约2000万t的酸性气体,污染大气环境,引发温室效应、光污染以及酸雨等环境污染问题,对人们的生存环境造成了严重的影响和危害,若不进行有效治理,后果不堪想象。而双极膜技术在处理这类酸性气体方面能够起到很有效的作用,比如说在脱硫技术上,就是先用碱溶液吸收SO2,再用双极膜系统去对吸收液(主要成分NaHSO4)进行电渗析处理,最后在酸室中得到的H2SO4,碱室中主要是Na2SO4和NaOH,再返回初始步骤吸收尾气。整个处理工艺基本实现了SO2零排放和资源化循环利用,不仅回收了有用物质SO2,而且减小了对环境的污染。双极膜中的酸室进行的反应如下:

2H+ + SO32-→ SO2+ H2O

在整个系统中有部分的SO32-被氧化成SO42-。双极膜的碱室中会发生以下反应:

HSO3- +OH-→ SO32- + H2O

而利用Na2SO3+SO2+H2O→2NaHSO3的反应,使SO2吸收、解析。Soxal[99]也验证了该技术能够有效应用到工业化废气脱硫中,具体作用过程如图4,该流程对SO2的回收效果是十分明显,并且能够实现H2SO4的高效循环利用,节约资源。

图4 Soxal TM 烟道气体脱硫

Fig.4 Soxal TM flue gas desulfurization

2.4 双极膜电渗析技术在大豆分离蛋白制备中的应用[100]

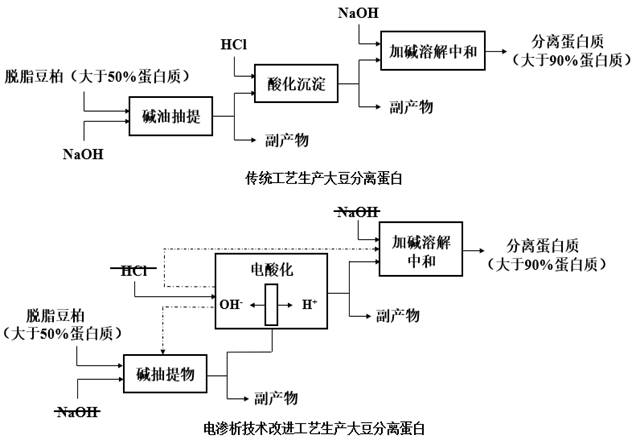

双极膜电渗析技术在大豆分离蛋白中的应用主要是指进一步对大豆进行脱脂处理,除去内部的非蛋白质成分,得到一种蛋白质含量高于90%的精制大豆蛋白产品,且这种产品中的氨基酸组成具有凝胶性、乳化性、保水性等功能,能够满足人体营养的一般需求,在食品工业领域有广泛的应用[101,102]。图5将传统的大豆分离蛋白工艺与电渗析双极膜技术的工作流程进行了一个对比:传统大豆蛋白的分离要经过萃取、沉淀、洗涤、再溶解、干燥等步骤,这种工艺不仅会造成大豆蛋白的变性、灰分含量过高以及蛋白含量较低,还会导致蛋白质溶解度在再溶解过程中发生改变[103]。而利用双极膜电渗析技术处理,在阴极产生NaOH,阳极对蛋白质溶液进行电酸化,最后经过干燥即可得到分离的蛋白质[104]。整个过程虽然操作时间较长,但是不需要额外地加酸和加碱,现场水解离会产生酸和碱,而且此方法得到的蛋白质也不易变性。同时,产生的酸和碱可以在处理过程的不同阶段被充分利用,从而大大地减少了水的消耗量,得到含盐量较低、具有理想的化学组成的产品。

图5 传统工艺与电渗析技术改进工艺生产大豆分离蛋白

Fig.5 Traditional technology and electrodialysis technology improved technology to produce soybean protein isolate

2.5 双极膜电渗析技术在水处理中的应用

目前,双极膜电渗析技术在水处理中也有应用,如冷却循环污水[90]、市政污水[105]、海水淡化[89,106]、高盐废水处理[107,108]、卤水[109]、硝酸铵废水[110]、谷氨酸废水[111]等,已经存在相对成熟的技术,并有一定的技术落地实施以及工业化应用。

3 双极膜在磷石膏资源化方面的利用研究

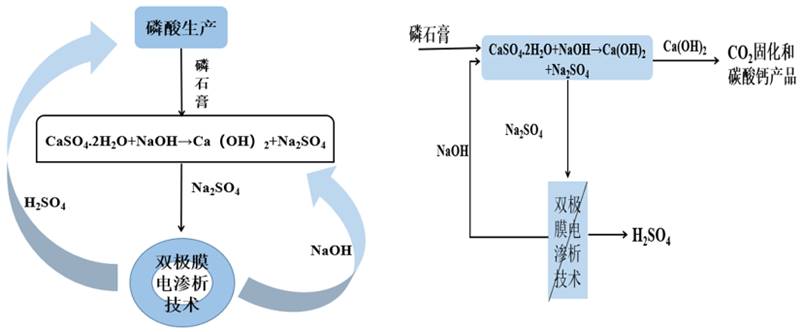

随着高分子技术的迅速发展,双极膜的应用技术也越来越广泛,目前已有部分研究表明双极膜电渗析技术可应用到磷石膏资源化利用上,图6展示了双极膜电渗析技术在磷石膏资源化利用中的作用过程,该过程主要通过处理磷石膏分解液以回收氢氧化钠和氨水,其中氢氧化钠的回收率已经超过了60%;有的研究学者也将双极膜电渗析技术应用到磷石膏浊液的分离中,借助硫酸钙在水中微量溶解的物理化学特性,制取硫酸和氢氧化钙浑浊液,并取得了较为良好的成效。武汉理工大学研究了用Na2SO4电解法回收磷石膏的零排放的初步研究中就是利用了双极膜电渗析技术[112],用阴离子交换膜制得一双室电解槽,使整体的处理效率、功耗都得以优化;Chaudhury[113]等利用双极膜电渗析(BMED)可将Na2SO4转化为NaOH和H2SO4,NaOH可以被回收用于溶解磷石膏,而H2SO4可以重新引入工业磷酸生产工艺或是用于提取磷石膏中有价金属,提高磷石膏的资源化利用效益,将磷石膏的综合利用过程转化称为一个更清洁、更循环的过程。

图6 双极膜电渗析技术在磷石膏资源化利用机理

Figure 6 The resource utilization mechanism of bipolar membrane electrodialysis technology in phosphogypsum

4 双极膜在磷石膏清洁加工循环利用方面的应用前景

环境治理的真谛是将污染物质分离富集提纯,环境治理的同时高附加值资源化;处于影响磷化工企业发展的主要制约因素之一的副产物磷石膏资源化利用以及清洁加工循环利用成为环境领域重点关注的热点之一,双极膜电渗析技术在国内外相对比较成熟,双极膜技术能使许多污染物分离富集,已经在许多方面进行应用,而在磷石膏清洁加工资源化和循环利用方面研究尚处于初步探索阶段,但是针对目前磷石膏的来源,以及其多种资源化的利用方法,可以借助双极膜技术形成磷石膏资源化生态圈,同时达到无害化和资源化处理。图7展示了双极膜技术在磷石膏资源化利用途径中能达到清洁加工的一个作用过程图,磷矿加工生产磷酸的同时副产磷石膏,磷石膏经过双极膜电渗析技术可以回收硫酸,整个过程对资源、能源进行了高效循环利用;随着社会经济和技术的快速发展,加上双极膜技术的无害化以及零污染等优点,双极膜在磷石膏资源化方面技术即将取代磷石膏原有的材料化技术,即将会形成磷化工企业独特的磷石膏资源化生态循环系统,降低磷化工企业生产成本的同时形成磷化工生态环保型企业链,缓解环境压力,解决磷石膏产量和推存量巨大以及附加值利用率低等问题,双极膜电渗析技术在不久的将来会成为磷化工企业实际运用过程中的颠覆性技术,同时还可能会普及于其他固体废弃物、废水、废气的高附加值资源化利用,成为环保领域的突破技术之一,为环境治理提供了一个新兴的研究思路和研究热点。

图7 双极膜在磷石膏清洁加工循环利用技术

Figure 7 Bipolar membrane recycling technology in phosphogypsum cleaning processing

5 结论与展望

磷石膏大量堆存的问题已成为目前制约磷化工企业发展的瓶颈问题,国内外虽然已经存在大量对磷石膏资源化利用以及无害化处理的研究,但由于成本较高、附加值利用率低、环境潜在风险较高、工艺复杂等问题,许多研究技术仍然停留于实验室阶段或者小试阶段,无法大规模的工业化应用;结合目前双极膜的优点和应用现状,其分离富集效果明显,且已存在部分的工业化应用,但双极膜在磷石膏资源化处理以及循环利用中的应用尚处于初步探索阶段,但根据目前双极膜的发展特点以及发展趋势,双极膜有望成为解决磷化工企业副产物磷石膏问题重要技术手段之一,提高磷石膏高附加值利用率,减少环境潜在风险,降低企业生产成本的同时副产物高附加值利用,为建立磷化工清洁生产生态环保型企业链提供研究方向和理论思路。

参考文献:

[1] Kumar SS, Kumar A, Singh S. Industrial wastes: Fly ash, steel slag and phosphogypsum-potential candidates to mitigate greenhouse gas emissions from paddy fields [J], Chemosphere,2020,241: 124824

[2] Sabrina F. Lütke, Marcos L.S. Oliveira, Luis F.O. Silva, et al. Nanominerals assemblages and hazardous elements assessment in phosphogypsum from an abandoned phosphate fertilizer industry[J]. Chemosphere,2020,256:127138

[3] José Luis Guerrero, Isidoro Gutiérrez-Álvarez, Fernando Mosqueda, et al. Evaluation of the radioactive pollution in the salt-marshes under a phosphogypsum stack system[J]. Environmental Pollution,2020,258:113729

[4] M.I. Romero-Hermida, V.Flores-Alés, S.J. Hurtado-Bermúdez, et al. Environmental Impact of Phosphogypsum-Derived Building Materials[J].International Journal of Environmental Research and Public Health,2020,17(12),4248

[5] Zhang W, Zhang F, Ma L, et al. An efficient methodology to use hydrolysate of phosphogypsum decomposition products for CO2 mineral sequestration and calcium carbonate production[J], Journal of Cleaner Production, 2020,259:120826

[6] Liu S, Fang P, Ren J, et al. Application of lime neutralised phosphogypsum in supersulfated cement[J]. Journal of Cleaner Production,2020,272(1):122660

[7] Zmemla R, Sdiri A, Naifar I, et al. Tunisian phosphogypsum tailings: Assessment of leaching behavior for an integrated management approach[J]. Environmental Engineering Research,2020,25(3):345-355

[8] Fornes IV, Vaiciukyniene D, Nizevičienė D, et al. A method to prepare a high-strength building material from press-formed phosphogypsum purified with waste zeolite[J]. Journal of Building Engineering,2021,34(4):101919

[9] Sun X, Zhang G, Cui P. Aspect ratio-controlled preparation of α-CaSO4·0.5H2O from phosphogypsum in potassium tartrate aqueous solution [J]. RCS Advances,2019,9(38): 21601-21607

[10] Song W, Zhou J, Wang B, et al. Production of SO2 Gas: New and Efficient Utilization of Flue Gas Desulfurization Gypsum and Pyrite Resources[J]. Industrial & Engineering Chemistry Research,2019,58,44:20450-20460

[11] Chen Q, Ding W, Sun H, et al. Indirect mineral carbonation of phosphogypsum for CO2 sequestration[J]. Energy,2020,206(1):118148

[12] Lin C, Dai W, Li Z, et al. Study on the inorganic synthesis from recycled cement and solid waste gypsum system: Application in grouting materials[J]. Construction and Building Materials,2020,251:118930

[13] Alaa M. Rashad. Phosphogypsum as a construction material[J]. Journal of Cleaner Production,2017,166:732-743

[14] Mashifana TP. Chemical treatment of phosphogypsum and its potential application for building and construction [J], Procedia Manufacturing,2019,35: 641-648

[15] M.I. Romero-Hermida, V. Flores-Alés, S.J. Hurtado-Bermúdez, et al. Environmental Impact of Phosphogypsum-Derived Building Materials[J]. International Journal of Environmental Research and Public Health,2020,17(12):4248

[16] Amrani M, Taha Y, Kchikach A, et al. Phosphogypsum recycling: new horizons for a more sustainable road material application[J]. Journal of Building Engineering,2020,30(7):101267

[17] Gong S, Li X, Song F. Preparation and Application in HDPE of Nano-CaSO4 from Phosphogypsum [J], ACS Sustainable Chemistry & Engineering,2020,8(11): 4511-4520

[18] Sun X, Li Z, Wang X. Single-Crystal Regular Hexagonal Microplates of Two-Dimensional α-Calcium Sulfate Hemihydrate Preparation from Phosphogypsum in Na2SO4 Aqueous Solution [J], Industrial & Engineering Chemistry Research,2020,59(31): 13979-13987

[19] Ma B, Jin Z, Su Y, et al. Utilization of hemihydrate phosphogypsum for the preparation of porous sound absorbing material[J]. Construction and Building Materials,2020,234:117346

[20] Wang B, Lian G, Lee X, et al. Phosphogypsum as a novel modifier for distillers grains biochar removal of phosphate from water[J]. Chemosphere,2020,238:124684.1-124684.8

[21] Schirmer T. Extraction of Rare Earth Elements from Phospho-Gypsum: Concentrate Digestion, Leaching, and Purification [J], Metals,2020,10(1):13

[22] Mi Y, Chen D, Wang A. Effects of phosphorus impurities on the preparation of α-calcium sulfate hemihydrate from waste phosphogypsum with the salt solution method under atmospheric pressure [J], CrystEngComm,2019,21(16): 2631-2640

[23] Wei J, Gu Y, Lv H, et al. A zero-emission method for recycling phosphogypsum using Na2SO4 electrolysis: Preliminary study[J]. Separation and Purification Technology,2021,259:118168

[24] Parnamae R, Mareev S, Nikonenko V. Bipolar membranes: A review on principles, latest developments, and applications [J], Journal of Membrane Science,2021,617:118538

[25] Tzanetakis N, Taama WM, Scott K. Salt splitting in a three-compartment membrane electrolysis cell [J], Filtration & Separation,2002,39(3):30-38

[26] Strathmann H, Krol J J, Rapp H J, et al. Limiting current density and water dissociation in bipolar membranes[J]. Journal of Membrane Science,1997,125(1):123-142

[27] Wang X, Wang Y, Zhang X, et al. Phosphate Recovery from Excess Sludge by Conventional Electrodialysis (CED) and Electrodialysis with Bipolar Membranes (EDBM) [J], Industrial & Engineering Chemistry Research,2013,52(45): 15896-15904

[28] Qiuyue, Wang, Yaoming, et al. Reclamation of Aniline Wastewater and CO2 Capture Using Bipolar Membrane Electrodialysis [J], ACS Sustainable Chemistry & Engineering,2016,4(10): 5743-5751

[29] Lin JY, Huang J, Ricard B, et al. Toward Resource Recovery from Textile Wastewater: Dye Extraction,Water and Base/Acid Regeneration Using a Hybrid NF-BMED Process [J], ACS Sustainable Chemistry,2015,9(9): 1993–2001

[30] Zhang X, Wang X, Chen Q, et al. Batch preparation of high basicity polyferric sulphate by hydroxide substitution from bipolar membrane electrodialysis [J], ACS Sustainable Chemistry & Engineering,2017,5(3): 2292-2301

[31] Thiel GP, Kumar A, Gómez-González A, et al. Utilization of Desalination Brine for Sodium Hydroxide Production: Technologies, Engineering Principles, Recovery Limits, and Future Directions [J], ACS Sustainable Chemistry & Engineering, 2017,5,12:11147-11162

[32] Ibáñez R, Pérez-González A, Gómez P, et al. Acid and base recovery from softened reverse osmosis (RO) brines. Experimental assessment using model concentrate [J], Desalination,2013,309:165-170

[33] Wang M, Wang K-k, Jia Y-x, et al. The reclamation of brine generated from desalination process by bipolar membrane electrodialysis[J]. Journal of Membrane Science,2014,452:54-61

[34] Rottiers T, Bruggen VdB, Pinoy L. Production of salicylic acid in a three compartment bipolar membrane electrodialysis configuration [J], Journal of Industrial and Engineering Chemistry,2017,54:190-199

[35] Zhou Y, Yan H, Wang X, et al. A closed loop production of water insoluble organic acid using bipolar membranes electrodialysis (BMED)[J]. Journal of Membrane Science,2016,520:345-353

[36] Zhang N, Peng S, Huang C, et al. Simultaneous regeneration of formic acid and carbonic acid from oxalate discharge by using electrodialysis with bipolar membranes (EDBM)[J]. Journal of Membrane Science,2007,309(1-2):56-63

[37] Kishida M, Harato T, Tokoro C, et al. In situ remediation of bauxite residue by sulfuric acid leaching and bipolar-membrane electrodialysis[J]. Hydrometallurgy,2017,170:58-67

[38] Fernandez-Gonzalez, Carolina, Ibanez, et al. Electrodialysis with Bipolar Membranes for Valorization of Brines[J]. Separation & Purification Reviews,2016,45(4):275-287

[39] Ghyselbrecht K, Silva A, Bruggen B, et al. Desalination feasibility study of an industrial NaCl stream by bipolar membrane electrodialysis[J]. Journal of environmental management,2014,140:69-75

[40] Ghyselbrecht K, Huygebaert M, Bruggen B, et al. Desalination of an industrial saline water with conventional and bipolar membrane electrodialysis[J]. Desalination,2013,318:9-18

[41] 李铭,梁欢,随婕斐,等.我国磷石膏资源化利用进展及前景展望[J].磷肥与复肥,2020,35(07):30-36.

LI M, Liang H, Sui J F, et al. Progress and prospect of resource utilization of phosphogypsum in China [J]. Phosphate fertilizer and compound fertilizer, 2020,35(07):30-36. (in Chinese)

[42] 付强强,沈彦辉,陈宏坤,等.磷石膏综合利用现状及建议[J],磷肥与复肥,2020,35(08): 53-55

Fu Q Q, Shen Y H, Chen H K, et al. Status and suggestions of comprehensive utilization of phosphogypsum [J], phosphate fertilizer and compound fertilizer,2020,35(08): 53-55(in Chinese)

[43] 饶轶晟,王凤霞.磷石膏资源化利用途径及展望[J],化工矿物与加工,2020,(8): 30-33

Rao Y S, Wang F X. The way and prospect of phosphogypsum resource utilization [J], Chemical Minerals & Processing,2020, (8): 30-33. (in Chinese)

[44] Zhang L, Zhang A, Li K, et al. Research on the pretreatment and mechanical performance of undisturbed phosphogypsum[J]. Case Studies in Construction Materials,2020,13, 00400

[45] 许彦明,蒙海宁,敖林,等.我国工业固体废弃物磷石膏预处理及综合利用综述[J],商品混凝土,2020(1):33-36

Xu Y M, Meng H N, AO L, et al. Review on pretreatment and Comprehensive Utilization of Phosphogypsum from Industrial solid waste in China [J]. Commercial Concrete,2020(1):33-36(in Chinese)

[46] Dai Q, Ren N, Ma L, et al. Research on dewaterability and properties of sewage sludge under modified phosphogypsum and acetic acid pretreatments[J]. Bioresource Technology,2018,264:268-276

[47] Chen X, Gao J, Zhao Y. Investigation on the hydration of hemihydrate phosphogypsum after post treatment [J], Construction and Building Materials,2019,229: 116864.1-116864.9

[48] Zeng L L, Bian X, Zhao L, et al. Effect of phosphogypsum on physiochemical and mechanical behaviour of cement stabilized dredged soil from Fuzhou, China[J]. Geomechanics for Energy and the Environment,2021,25:100195

[49] Marco D, Marcos A, María C, et al. Acosta. Predicting spatial distribution of heavy metals in an abandoned phosphogypsum pond combining geochemistry, electrical resistivity tomography and statistical methods[J]. Journal of Hazardous Materials,2019,374:392-400

[50] K. Qamouche, A. Chetaine, A. Elyahyaoui, et al. Radiological characterization of phosphate rocks, phosphogypsum, phosphoric acid and phosphate fertilizers in Morocco: An assessment of the radiological hazard impact on the environment[J]. Materials Today: Proceedings,2020,27(4):3234-3242

[51] Zrelli R E, Rabaoui L, Abda H, et al. Characterization of the role of phosphogypsum foam in the transport of metals and radionuclides in the Southern Mediterranean Sea[J]. Journal of hazardous materials,2019,363(5):258-267

[52] Wang J. Utilization effects and environmental risks of phosphogypsum in agriculture: A review [J], Journal of Cleaner Production,2020,276:123337

[53] Huang Y, Qian J, Kang X, et al. Belite-calcium sulfoaluminate cement prepared with phosphogypsum: Influence of P2O5 and F on the clinker formation and cement performances[J]. Construction and Building Materials,2019,203(10):432-442

[54] Li B, Shu J, yang L, et al. An innovative method for simultaneous stabilization/solidification of PO43− and F− from phosphogypsum using phosphorus ore flotation tailings [J], Journal of Cleaner Production,2019,235: 308-316

[55] Yang J, Zhu B, Ma L, et al. Investigation of Al2O3 and Fe2O3 transmission and transformation during the decomposition of phosphogypsum[J]. Chinese Journal of Chemical Engineering,2019,27(05):1125-1131.

[56] Antonick PJ, Hu Z, Fujita Y, et al. Bio- and mineral acid leaching of rare earth elements from synthetic phosphogypsum[J]. The Journal of Chemical Thermodynamics,2019,132:491-496

[57] Geraldo R H, Costa A, Kanai J, et al. Calcination parameters on phosphogypsum waste recycling[J]. Construction and Building Materials,2020,256:119406

[58] Kuzmanović P, Todorović N, Mrđa D, et al. The possibility of the phosphogypsum use in the production of brick: Radiological and structural characterization[J]. Journal of Hazardous Materials,2021,413(10):125343

[59] Wang Q, Jia R. A novel gypsum-based self-leveling mortar produced by phosphorus building gypsum[J], Construction and Building Materials,2019,226:11-20

[60] Sabrina R.Pinto, Caroline Angulski da Luz, Guilherme S. Munhoz, et al. Resistance of phosphogypsum-based supersulfated cement to carbonation and chloride ingress[J].Construction and Building Materials,2020,263:120640

[61] Rabi J A, Silva N. Radon exhalation from phosphogypsum building boards: symmetry constraints, impermeable boundary conditions and numerical simulation of a test case[J], Journal of Environmental Radioactivity,2006,86(2):164-175

[62] Jiang G, Wu A, Wang Y, et al. Low cost and high efficiency utilization of hemihydrate phosphogypsum: Used as binder to prepare filling material[J]. Construction and Building Materials,2018,167:263-270

[63] Li X, Zhang Q, Shen Z, et al. L-aspartic acid: A crystal modifier for preparation of hemihydrate from phosphogypsum in CaCl2 solution[J]. Journal of Crystal Growth,2019,511:48-55

[64] Li X, Zhang Q, Ke B, et al. Insight into the effect of maleic acid on the preparation of α-hemihydrate gypsum from phosphogypsum in Na2SO4 solution [J], Journal of Crystal Growth,2018,493:34-40

[65] Zhao L, Zhang Q, Li X, et al. Adsorption of Cu (II) by phosphogypsum modified with sodium dodecyl benzene sulfonate[J]. Journal of Hazardous Materials,2019,387:121808

[66] Lachehab A, Mertah O, Kherbeche A, et al. Utilization of phosphogypsum in CO2 mineral sequestration by producing potassium sulphate and calcium carbonate[J]. Materials Science for Energy Technologies,2020,3:611-625

[67] Zhang W, Zhang F, Ma L, et al. CO2 capture and process reinforcement by hydrolysate of phosphogypsum decomposition products[J]. Journal of CO2 Utilization,2020,36:253-262

[68] Ennaciri Y, Alaoui-Belghiti H E, Bettach M. Comparative study of K2SO4 production by wet conversion from phosphogypsum and synthetic gypsum [J], Journal of Materials Research and Technology,2019,8(3):2586-2596

[69] Ding W J, Chen Q J, Sun H J, et al. Modified phosphogypsum sequestrating CO2 and characteristics of the carbonation product[J]. Energy,2019,182:224-235

[70] Peng X, Deng Y G, Liu L, et al. The addition of biochar as a fertilizer supplement for the attenuation of potentially toxic elements in phosphogypsum-amended soil[J]. Journal of Cleaner Production,2020,277(2):124052

[71] Jihen Jalali, Pierre Gaudin, Hervé Capiaux, et al. Isolation and screening of indigenous bacteria from phosphogypsum-contaminated soils for their potential in promoting plant growth and trace elements mobilization[J]. Journal of Environmental Management,2020,260:110063.1-110063.9

[72] Ma B, Jin Z, Su Y, et al. Utilization of hemihydrate phosphogypsum for the preparation of porous sound absorbing material[J]. Construction and Building Materials,2020,234:117346

[73] Cuadri A.A, Pérez-Moreno S., Altamar C.L., et al. Phosphogypsum as additive for foamed bitumen manufacturing used in asphalt paving[J]. Journal of Cleaner Production,2021,283:124661

[74] Amrani M, Taha Y, Kchikach A, et al. Phosphogypsum recycling: new horizons for a more sustainable road material application[J]. Journal of Building Engineering,2020,30:101267

[75] Zhou J, Li X Q, Zhao Y, et al. Preparation of paper-free and fiber-free plasterboard with high strength using phosphogypsum[J]. Construction and Building Materials,2020,243:118091

[76] Jun Zhou, Dongxue Yu, Zhu Shu, et al. A novel Two-step Hydration Process of preparing cement-free non-fired bricks from waste phosphogypsum[J]. Construction and Building Materials,2014,73:222-228

[77] Tian Tian, Yun Yan, Zhihua Hu, et al. Utilization of original phosphogypsum for the preparation of foam concrete[J].Construction and Building Materials,2016,115:143-152

[78] Wang Q, Cui Y, Xue J. Study on the improvement of the waterproof and mechanical properties of hemihydrate phosphogypsum-based foam insulation materials [J].Construction and Building Materials,2020,230: 117014

[79] Qi Sun, Shuo Tian, Qingwei Sun, et al. Preparation and microstructure of fly ash geopolymer paste backfill material[J]. Journal of Cleaner Production,2019,225:376-390

[80] Gu K, Chen B, Pan Y. Utilization of untreated-phosphogypsum as filling and binding material in preparing grouting materials [J],Construction and Building Materials,2020,265: 120749

[81] Marja Salo, Oleg Knauf, Jarno Mäkinen, et al. Integrated acid leaching and biological sulfate reduction of phosphogypsum for REE recovery[J]. Minerals Engineering,2020,155:106408

[82] Ines Hammas-Nasri, Karima Horchani-Naifer, Mokhtar Férid, et al. Production of a rare earths concentrate after phosphogypsum treatment with dietary NaCl and Na2CO3 solutions[J]. Minerals Engineering,2019,132:169-174

[83] Masmoudi-Soussi A, Hammas-Nasri I, Horchani-Naifer K, et al. Rare earths recovery by fractional precipitation from a sulfuric leach liquor obtained after phosphogypsum processing[J]. Hydrometallurgy,2020,191:105253

[84] Li F R, Jia Y X, Guo R Q, et al. Preparation of composite anion-exchange membrane with acid-blocking performance for brine reclamation by bipolar membrane electrodialysis[J].Separation and Purification Technology,2021,254:117587

[85] Zhang H, Wang H, Jiao K, et al. pH-differential design and operation of electrochemical and photoelectrochemical systems with bipolar membrane[J]. Applied Energy,2020,268:115053

[86] Pärnamäe R, Mareev S, Nikonenko V, et al. Bipolar membranes: A review on principles, latest developments, and applications [J], Journal of Membrane Science,2021,617:118538

[87] Wu S, Yang W, Yan H, et al. A review of modified metal bipolar plates for proton exchange membrane fuel cells[J]. International Journal of Hydrogen Energy,2021,46(12):8672-8701

[88] Xia Chen, George Q.Chen, Qiuyue Wang, et al. Transforming salty whey into cleaning chemicals using electrodialysis with bipolar membranes[J]. Desalination,2020,492:114598

[89] Yingying Zhao, Lurong Wang, Zhiyong Ji, et al. Collaborative disposal of problematic calcium ions in seawater and carbon and sulfur pollutants in flue gas by bipolar membrane electrodialysis[J]. Desalination,2020,494:114654

[90] Jiang G, Li H, Xu M, et al. Sustainable reverse osmosis, electrodialysis and bipolar membrane electrodialysis application for cold-rolling wastewater treatment in the steel industry [J], Journal of Water Process Engineering,2021,40:101968

[91] Mani KN. Electrodialysis water splitting technology [J], Journal of Membrane Science,1991,58(2): 117-138

[92] Herrero-Gonzalez M, Diaz-Guridi P, Dominguez-Ramos A, et al. Highly concentrated HCl and NaOH from brines using Electrodialysis with Bipolar Membranes[J]. Separation and Purification Technology,2020,242:116785.

[93] Vitalii Kravtsov, Irina Kulikova, Sergey Mikhaylin, et al. Alkalinization of acid whey by means of electrodialysis with bipolar membranes and analysis of induced membrane fouling[J]. Journal of Food Engineering,2020,277:109891

[94] Sheldeshov N V, Zabolotsky V I, Kovalev N V, et al. Electrochemical characteristics of heterogeneous bipolar membranes and electromembrane process of recovery of nitric acid and sodium hydroxide from sodium nitrate solution[J]. Separation and Purification Technology,2020,241:116648

[95] 汪耀明. 双极膜电渗析法生产有机酸过程的几个关键科学问题研究[D],中国科学技术大学,2011,13-32

Wang Y M. Research on several key scientific problems in the production of organic acids by bipolar membrane electrodialysis [D]. University of Science and Technology of China,2011,13-32(in Chinese)

[96] Chunxiao Lei, Zichao Li, Qi Gao, et al. Comparative study on the production of gluconic acid by electrodialysis and bipolar membrane electrodialysis: Effects of cell configurations[J]. Journal of Membrane Science,2020,608:118192

[97] 陈霞,蒋晨啸,汪耀明,等.反向电渗析在新能源及环境保护应用中的研究进展[J].化工学报,2018,69(01):188-202.

Chen Xia, Jiang Chenxiao, Wang Yaoming, et al. Research progress of reverse electrodialysis in new energy and environmental protection [J]. CIESC Journal,2018,69(01):188-202(in Chinese)

[98] Jeong K I, Oh J Y, Song S A, et al. A review of composite bipolar plates in proton exchange membrane fuel cells: Electrical properties and gas permeability[J]. Composite Structures,2021,262(14):113617

[99] 徐铜文,何炳林.双极膜--新的工业革命[J], 世界科技研究与发展,2000(03):19-27

Xu T W, He B L. Bipolar membrane: A New Industrial Revolution [J]. World Science & Technology Research and Development,2000(03):19-27(in Chinese)

[100] Bazinet L, Lamarche F, Ippersiel D. Ionic balance: a closer look at the K+ migrated and H+ generated during bipolar membrane electro-acidification of soybean proteins [J], Journal of Membrane Science,1999,154(1): 61-71

[101] Bazinet L, Lamarche F, Ippersiel D. Bipolar-membrane electrodialysis: Applications of electrodialysis in the food industry [J], Trends in Food Science & Technology,1998,9(3): 107-113

[102] 李晓东.功能性大豆食品(功能性食品及其加工技术丛书)[M].化学工业出版社,2006.59-92

Li X D. Functional soybean food (Functional Food and processing Technology series)[M]. Chemical Industry Press,2006.59-92(in Chinese)

[103] 吴加根.谷物与大豆食品工艺学[M].中国轻工业出版社,1995.452-458

Wu J G. Cereal and soybean Food Technology [M]. China Light Industry Press,1995.452-458(in Chinese)

[104] 李丹,吴建平.大豆分离蛋白的电酸化法生产[J],食品与机械,1999(4): 20-20

Li D, WU J P. Production of soybean protein isolate by electric acidification [J]. Food & Machinery, 1999(4): 20-20

[105] AzadiAghdam M, Achilli A, Snyder S A, et al. Increasing water recovery during reclamation of treated municipal wastewater using bipolar membrane electrodialysis and fluidized bed crystallization[J]. Journal of Water Process Engineering,2020,38:101555

[106] Yingying Zhao, Jianhang Wang, Zhiyong Ji, et al. A novel technology of carbon dioxide adsorption and mineralization via seawater decalcification by bipolar membrane electrodialysis system with a crystallizer[J]. Chemical Engineering Journal,2020,381:122542

[107] Sangeetha, Dharmalingam, Krishnaveni, et al. Evaluation of synthetic salt water desalination by using a functionalized polysulfone based bipolar membrane electrodialysis cell [J], Desalination the International Journal on the Science & Technology of Desalting & Water Purification,2014,344: 189-197

[108] Campione A, Gurreri L, Ciofalo M, et al. Electrodialysis for water desalination: A critical assessment of recent developments on process fundamentals, models and applications[J]. Desalination,2018,434:121-160

[109] Mònica Reig, César Valderrama, Oriol Gibert, et al. Selectrodialysis and bipolar membrane electrodialysis combination for industrial process brines treatment: Monovalent-divalent ions separation and acid and base production[J]. Desalination,2016,399:88-95

[110] Ben Ali M, Rakib M, Laborie S, et al. Coupling of bipolar membrane electrodialysis and ammonia stripping for direct treatment of wastewaters containing ammonium nitrate[J]. Journal of Membrane Science,2004,244(1):89-96

[111] Wang Q, Yang P, Cong W. Cation-exchange membrane fouling and cleaning in bipolar membrane electrodialysis of industrial glutamate production wastewater[J], Separation and Purification Technology, 2011,79(1): 103-113

[112] Wei Jucai, Gu Yueyuan, Lv Hang, et al. A zero-emission method for recycling phosphogypsum using Na2SO4 electrolysis: Preliminary study[J]. Separation and Purification Technology,2021,259:118168

[113] Monat L, Chaudhury S, Nir O. Enhancing the Sustainability of phosphogypsum Recycling by Integrating Electrodialysis with Bipolar Membranes [J], ACS Sustainable Chemistry & Engineering,2020,8(6): 2490-2497